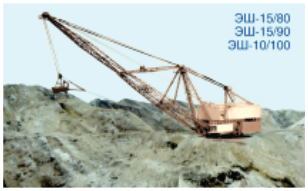

Walking draglines

In 1948 serial production of the first in the USSR ЭШ-1 walking dragline was initiated at NKMZ.

Walking draglines feature the full-revolving electric-operated earth-moving machines fitted with the crank-type walking mechanisms. This design covered by patents is distinguished by reliability and long service life.

Walking draglines are designed to excavate soils of the 1-st to 4-th categories of hardness inclusively when carrying out overburden operations through the use of the vehicle-free technology with the rock being disposed either to the workedout area or on the opencast flank. In so doing soils of the 3-rd and 4-th categories shall be prelimenarily loosened by blasting .

These draglines can be used for operation in opencast collieries, open pits and quarries as well as during construction of canals, irrigation systems and various water-development plants.

Being very reliable in operation, draglines made at NKMZ are employed now to perform about 50% of the earth-moving works in the CIS with their share in the fleet of excavating machines amounting, for instance, up to 80% of the walking draglines in Russia. Today, NKMZ JSC produces reliable, high-duty mobile machines with low soil pressure characteristics which enable to operate them on soft ground.

The following advanced designs provide high performances of the draglines:

- Articulated structure of the boom made of rolled angles provides simple and easy visual control, maintenance and repairs of structural members

- Support frame (mounting base) and swinging platform made up of sections joined with high-strength bolts facilitate easy assembling and maintenance through application of advanced technologies

- Bucket of a new design with improved body and geometry enables to operate the dragline under variable geological and excavation conditions

- Small-sized semiconductors including static exciters used instead of magnetic amplifiers and a 3-machine converting unit enable to reduce dynamic loads in transient processes, save electric power and eliminate resetup of the electric drive by seasons

- Main converting unit with smooth speedup and induction motors with automatic excitation control ensure steady operation of the opencast mines

- Smooth acceleration of the main conversion unit and automatic regulation of the synchronous motor excitation ensure the stability of the career network;

Due to the more severe geological and excavation conditions in a number of opencasts and in view of the growing need of the walking draglines with higher reliability, smaller weight and lower power consumption, the type ЭШ-15/90 dragline was designed and made at NKMZ not long ago.