ENGINEERING

Company engineering policy

Design-and-engineering and research-and-development school of NKMZ is known for its unique machines in the field of rolling-mills, draglines, press-forging and handling equipment engineering.

Company engineering policy consists in bringing scientific-research and experimental development works to production stage.

Due to this policy conditions for continuous implementation of advanced technological processes in metallurgical, welding, mechanical assembly and other divisions are created.

Computer system of production design engineering used at NKMZ Central Europe is based on modern software and hardware facilities. It realizes product data management through the whole life cycle: from conceptual engineering to operation stage.

PRODUCTION TECHNOLOGIES

Steelmaking

Process of quality steel production

Fully upgraded and formed according to its own engineering the steelmaking technological complex of NKMZ Central Europe includes: 1 electric arc furnace EAF with the capacity of 50 t; 2 electric arc furnaces EAF with the capacity of 12 t; 1 electric arc furnace EAF with the capacity of 5 t; 2 after-furnace ladle steel treatment units “Ladle-furnace”; steel vacuum degassing area based on the steam-jet pump and 4 vacuum chambers including vacuum chamber for VD and VOD.

Metal smelting is effected in steelmaking units with minimum time consumption, then metal is secondary treated in the ladle using the «Ladle-furnace» unit and vacuum degassed. Depending on the preset chemical composition and required properties of steel casting may be performed either in vacuum by top pouring or in air by bottom pouring.

Technical capabilities of steelmaking allow to produce forging ingots weighing from 1,6 to 170 t and up to 200 t of liquid metal for steel casting producing..

FOUNDRY

Casting processes design

Technical capacities of foundry allows castings producing of carbon, alloyed, high-alloyed steel grades; of grey, high-strength, bearing and special cast iron; of bronzed alloys.

Castings are made for machines of own production, as well as for other companies manufacturing special-purpose equipment: hydrotechnical, power-generating, ship-building, handling, mining, and metallurgical production.

There is a fleet of centrifugal casting machines for non-ferrous castings producing. Modern kneading-and-mixing machinery, manufactured by FAT and GUT companies (Germany), usage of new materials while making casting molds as per “Furan-process” provides possibility of the castings obtaining of the following weight (in tons)

Usage of computer systems of engineering analysis (CAE) by MAGMASoft (Germany) and LVMFlow (Russia) allows to develop technological procedures of castings producing having guaranteed high quality.

PRESS-FORGING FACILITIES

Automated forging complexes

The technical capacity of press-forging facilities enables to produce forgings with weight from 0,2 t up to 110 t by using forging ingots weighing from 1,6 up to 170 t, out of carbon, structural, tool and high-alloyed steel grades.

Open die forging process is realized with automated forging complexes in technological interconnection with reheating, heat-treating and handling equipment under control of automated process control systems (APCS).

HEAT TREATMENT FACILITIES

Technical capabilities of heat treatment facilities allow to accomplish various types of heat treatment and to provide required physical and mechanical properties of products.

Automated Process Control Systems (APCS) accomplish full maintenance and stabilization of thermal mode in the furnace, according to the preset programs of heating, cooling and energy saving modes, providing differential temperature up to ±5°C.

Big fleet of new heat-treatment furnaces and devices is equipped with:

- efficient impulse heating and cooling systems on high-speed gas burners basis, equipped with electrical ignition, flame control and implemented in cooling air supply lance;

- lining from modern ceramic fiber, low inertia, refractory and heat-insulating materials produced by such companies as Parok (Finland) and Keratech (Czech Republic);

- high-speed burners with impulse system of gas burning.

METALWORKS PRODUCTION

General description of metalworks production

Design-and-engineering and research-and-development school of NKMZ is known for its unique machines in the field of rolling-mills, draglines, press-forging and handling equipment engineering.

Company engineering policy consists in bringing scientific-research and experimental development works to production stage.

Due to this policy conditions for continuous implementation of advanced technological processes in metallurgical, welding, mechanical assembly and other divisions are created.

Computer system of production design engineering used at NKMZ Central Europe is based on modern software and hardware facilities. It realizes product data management through the whole life cycle: from conceptual engineering to operation stage.

Engineering and technical staff is certified according to the following norms and standards: ДНАОП 0.00-1,07-94 Rules for Design and Safe Operation of Pressure Vessels; ДНАОП 0.00-1,11-98 Rules for Design and Safe Operation of Steam and Hot Water Pipelines; ДНАОП 0.00-1,01-07 Rules for Design and Safe Operation of Cargo Cranes; СНиП 3.05.03-85 Building Codes and Regulations. Heat Networks; СНиП 3.05.04-85 Building Codes and Regulations. Water-supply and sewerage outdoor networks and structures, and other standards, regulations and specifications providing high quality of welding works.

Production personnel is certified in accordance with

ДНАОП 0.00-1,16-96 as per welding methods:

- manual arc welding (111);

- submerged arc welding with wire electrode (121);

- metal-arc inert gas welding (131);

- metal-arc active gas welding (135);

- flux cored wire metal-arc welding with active gas shield (136);

- flux cored wire metal-arc welding with inert gas shield (137);

- tungsten inert gas arc welding with filler metal wire or without it (141).

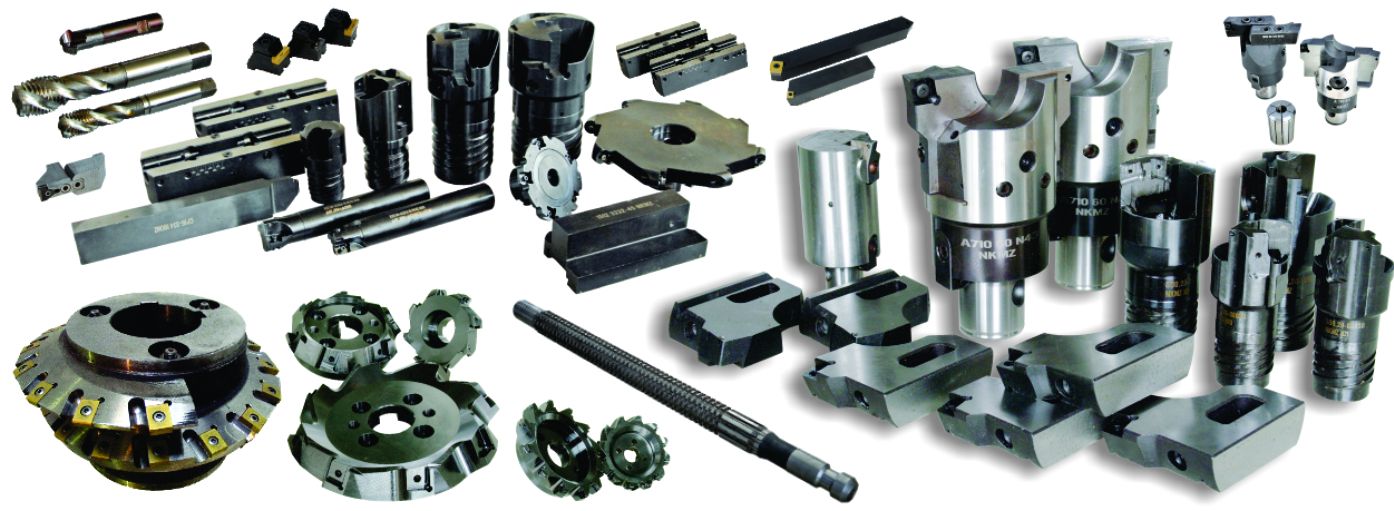

TOOL-MAKING FACILITIES

MECHANICAL ASSEMBLY PRODUCTION

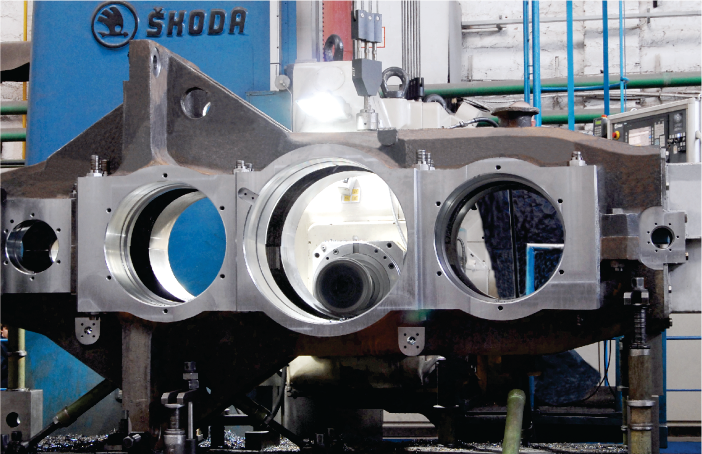

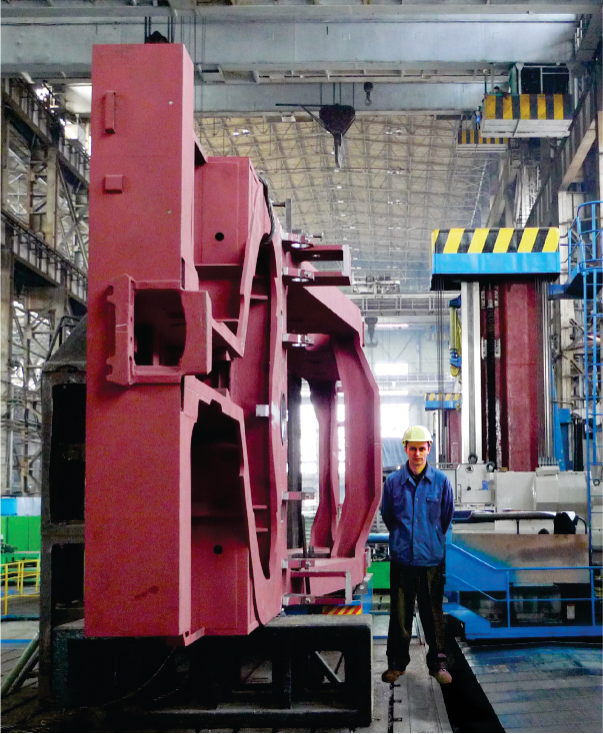

Fleet of metal-cutting equipment totals approximately 820 machines and machining centers including machines produced by German, Italian, Swiss, Japanese, etc. companies.

Processes providing machining of parts weight of which ranges from several grams to 300 tons are implemented.

Machining of complex box-shaped and basic parts makes no difficulty for PJSC NKMZ.

Capacity of PJSC NKMZ and its engineering and technical potential allow to manufacture almost any of mechanical engineering products meeting requirements of international standards and requests of the most discerning customers.

AUTOMATION

Design and production center “NKMZ- Automatics”

The design and production center (DPC) “NKMZ-Automatics” is an official partner and authorized system integrator of Siemens AG automation and drive department as well as of such companies as Schneider-Electric and Rittal.

The center incorporates powerful research and development department the design engineers of which with their high proficiency and vast experience develop process control software of any degree of complexity for all branches of heavy industry and almost for all fields of mechanical engineering.

Within the scope of APCS realization the software development is performed at different automation levels: PCL level – with controllers from Siemens, Schneider-Electric, ABB, GE Fanuc and others; APCS level – SCADA -systems (Siemens WinCC, InTouch, FactoryLink and others); Integration level – systems are based on DBMS ORACLe, MS SQL, designed for APCS engineering data integration into enterprise data system; equipment status monitoring systems and technology implementation with provision of automatically recorded reports for managerial staff.

The new systems are developed on the basis of gained experience and in accordance with corporate standards for software design and development. .

The SCADA-systems from world leading manufacturers are used for development of visualization systems.