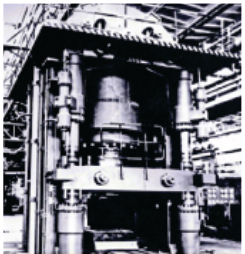

These presses are designed to stamp large-sized parts made of aluminum and titanium alloys and steel. Due to the high specific pressure developed in the dies, such presses can be used to make forgings of intricate shapes and large sizes with the minimum tolerances being maintained. NKMZ produces hydraulic close die forging presses up to 750 MN in force.

Advantages:

- High accuracy of stampings is assured by timing system, which provides the parallelism between the table and the walking beam

- Maximum liquid pressure in working cylinders is assured by multiplying gears

- Process control automatic system of beam travel and speed, liquid pressure in cylinders, process capacity eccentricity and tension in basic parts

- Availability of ejectors for stamped parts removal