High strength nodular iron rolls

It is used in the roughing stands of bars and sections, especially the BD2 mills for rail & beams. Compared with other nodular iron rolls, NC rolls have unique materials and heat treatment processes ensuring they are good enough to replace the traditional cast steel rolls but with a better life.

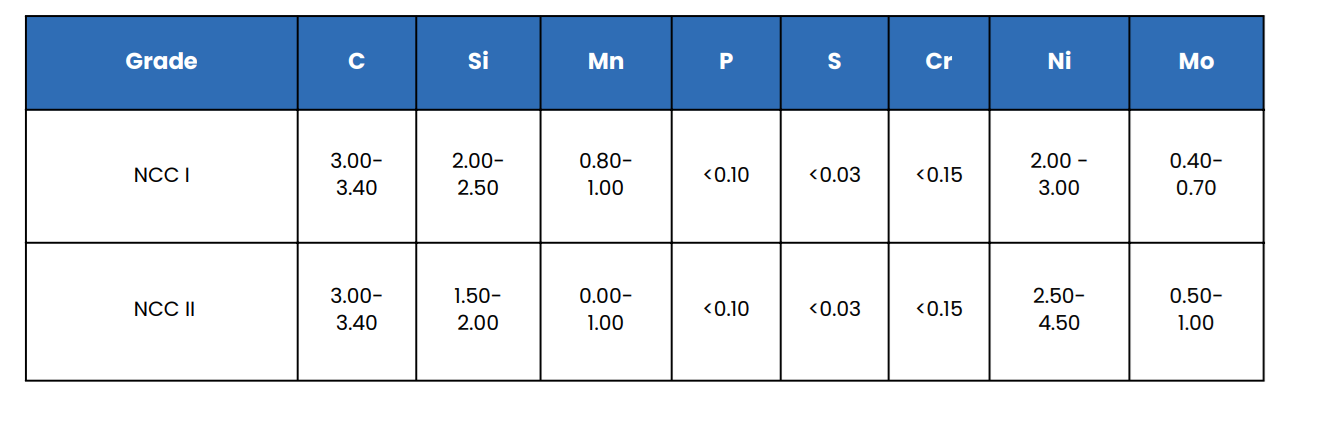

We control the carbide at a very low level (less than 5%) by reducing the chrome down to 0.3%, raising the silicon, and applying isothermal quenching to make the carbide solid solution into the matrix. Meanwhile, we can achieve a matrix of tempered sorbite/bainite by applying heat treatment and increasing nickel. This type of matrix has much better performance than perlite on the resistance of wear, fire crack, and impact, especially the excellent red hardness thanks to the molybdenum.