Alloy Steel Rolls

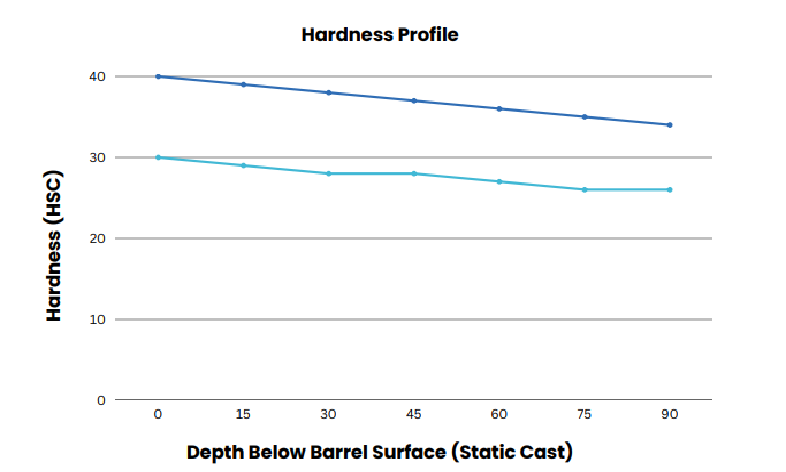

Alloy cast steel rolls are manufactured with high quality steel molten by arc furnance, due to the advanced casting and treatment technique, such rolls is of very high intensity. Owing to its excellent performances of anti-heat crack, tenacity ad wear-resistance, it is appropriate to be used for rough and intermediate stands of selection rolling mill, used as back-up rolls of

hot strip rolling mill. Its metallographic structure is made of pearlite or temper sorbite.

The alloy steel tolls are widely used in the BD mill and roughing stands of heavy section mills, universal mils and rail & beam mills. This type of roll often has deep grooves in the roll body, so we make it by static cast. Due to the low carbon in the chemistry, we can hardly see graphite and carbide in the microstructure.

The matrix is perlite & ferrite and little tempered sorbite. Based on high strength and tougss, it can work at a very tough condition, even with little ot without cooling water. So, it is welcomed

while rolling stainless steel, titanium and other high alloy products, or worked on the billet mills, BD mills against massive hit.