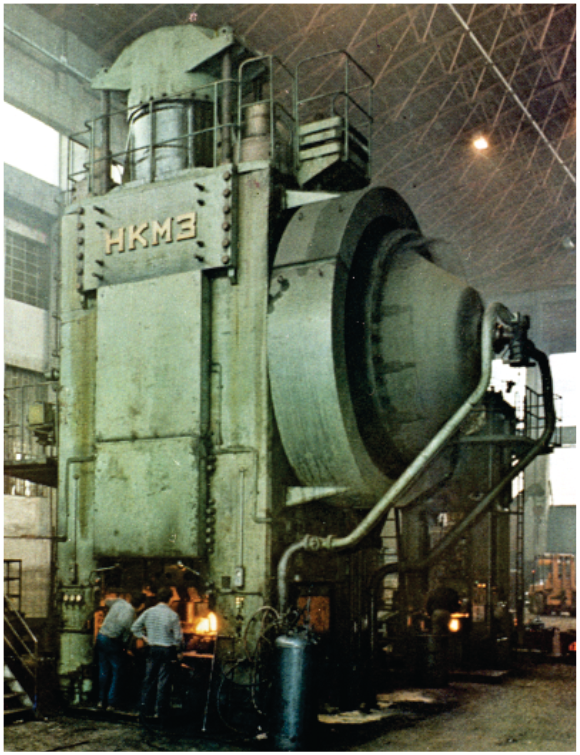

Crank presses production was set up in the early 50-s. 15MN crank hot die forging press was among the first manufactured. Hereafter, the range of presses manufactured at NKMZ was extended.

Due to high rigidity of the frame and crank-and-rod mechanism, the present type of pressure metal treatment equipment provides high productivity along with forgings high quality and low maintenance costs.

Presses are equipped with the device for blank arrangement to the first position of die, transporters for blank infeed and stamped forging removal, devices for die installation and die bushes changing, technological force and friction bearings temperature control monitors, die process lubrication device..

Equipment with “NKMZ” trademark gave a good account of itself in Italy, France, Germany, Brazil, China and other countries.

Presses are intended for part blanks hot stampings at mass and batch production workshops.

Maximal economical effect is provided by the press when it is used for blanks production in automobile, tractor, and aircraft industry, as also in transport and agricultural engineering.

Advantages:

- High efficiency, due to the drive high speed and energy capacity

- Reliable, crank-and-rod mechanism as also frame increased roughness

- Provides forgings high quality on account of the slide accurate direction