Adamite rolls

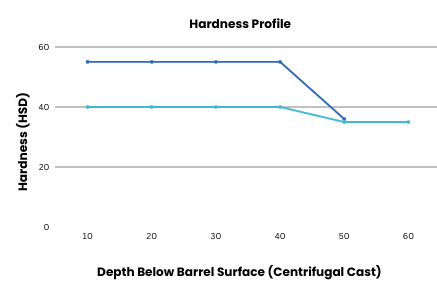

According to different requirements, the carbide contents of the adamite rolls vary. When wears resistance is required content of the carbide must be higher, but when strength is the main factor, it is necessary to select the lower content of the carbide. The heat treatment is normalized and tempered. A soft anneal will transform the pearlite to nodular from when the hardness is lower, while the strength relief anneals has no influence on the structure mbe adopted when higher. The lower hardness rolls have better strength properties and better resistance to fire cracking.According to different requirements, the carbide contents of the adamite rolls vary. When wears resistance is required content of the carbide must be higher, but when strength is the main factor, it is necessary to select the lower content of the carbide. The heat treatment is normalized and tempered. A soft anneal will transform the pearlite to nodular from when the hardness is lower, while the strength relief anneals has no influence on the structure mbe adopted when higher. The lower hardness rolls have better strength properties and better resistance to fire cracking.