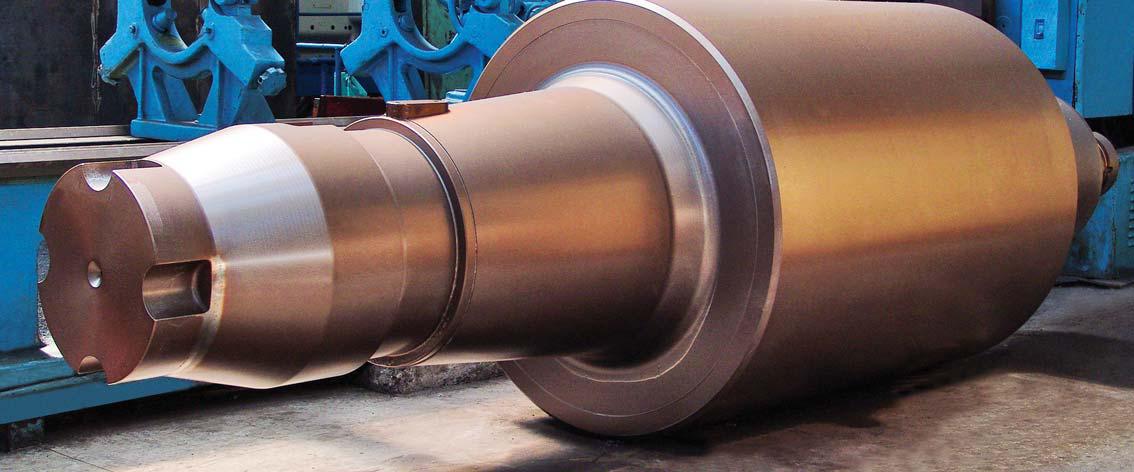

Backup rolls for cold- and hot-rolling mills

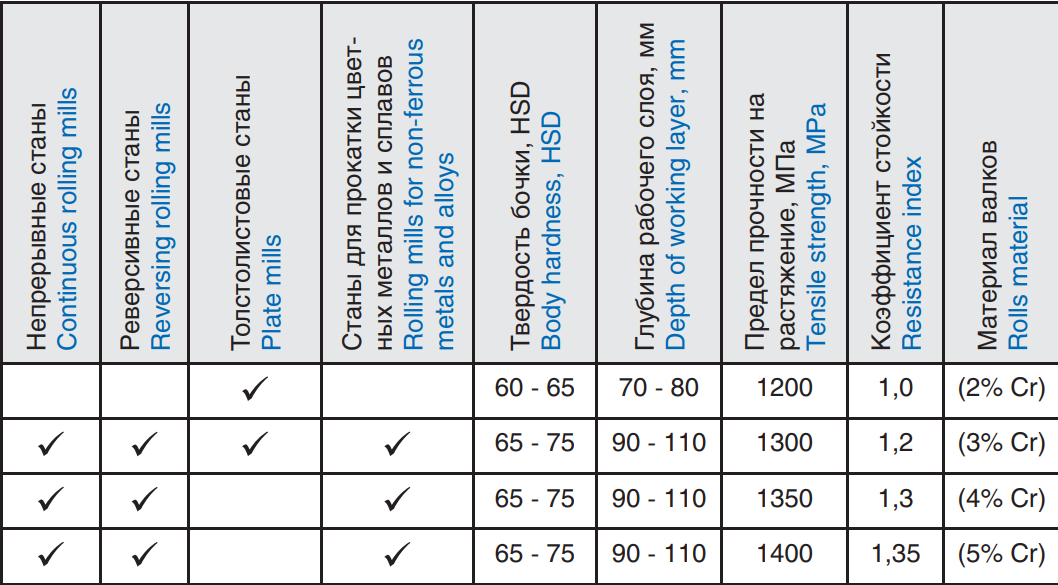

- High wear resistance across entire depth of working layer owing to presence of secondary chromium carbides dissolved in tempered martensite-bainite matrix.

- Forged homogenous structure, excluding the presence of weaknesses and pores.

- High level of barrel and necks strength and plastic properties.

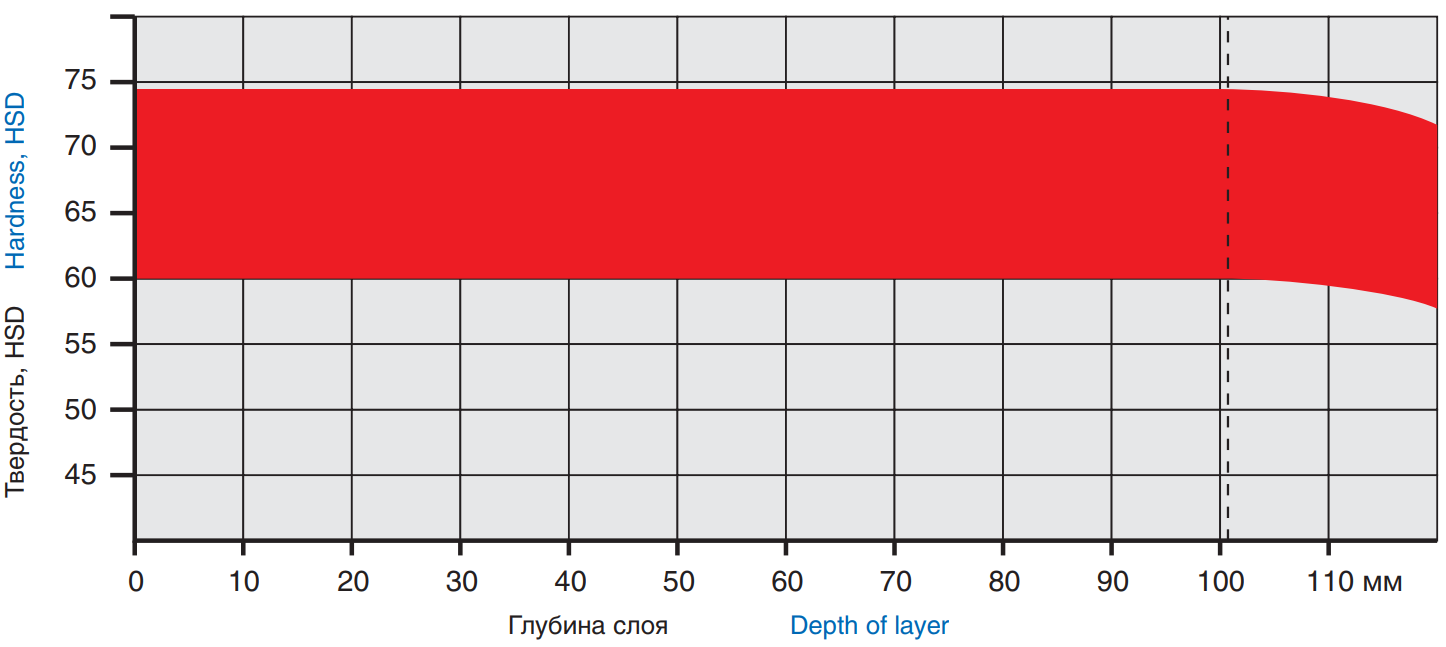

Hardened working layer with high and constant hardness. - Uniform wear profile, high shock resistance at emergencies in the mill.

- High operational characteristics ensured by balanced campaign period and regrinding scope

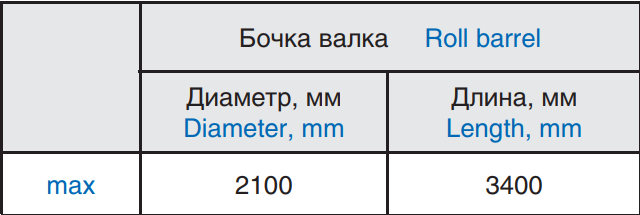

Roll production technical capabilities –

30-50 rolls/month.

Barrel hardness variation – max 3 HSD

Hardness distribution along the depth of roll barrel hardened layer

DIFFERENTIAL HEAT TREATMENT

NKMZ Central Europe constructed equipment and developed technology for differential heat treatment (DHT) of backup rolls barrels. This DHT ensures the depth of hardened layer up to 110 mm.