Work rolls for hot-rolling mill

- High wear resistance across entire depth of working layer owing to presence of special carbides uniformly dissolved in matrix.

- Microstructure of work layer – martensite decomposition products (secondary sorbite).

- Forged homogenous structure, excluding the presence of weaknesses and pores.

- High level of barrel and necks strength and plastic properties.

- High wear and thermal (fire) cracks formation resistance, abrasive wear and contact loads resistance.

- Hardened working layer with high and constant hardness.

- Uniform wear profile, high shock resistance at emergencies in the mill.

- High operational characteristics ensured by balanced campaign period and regrinding scope.

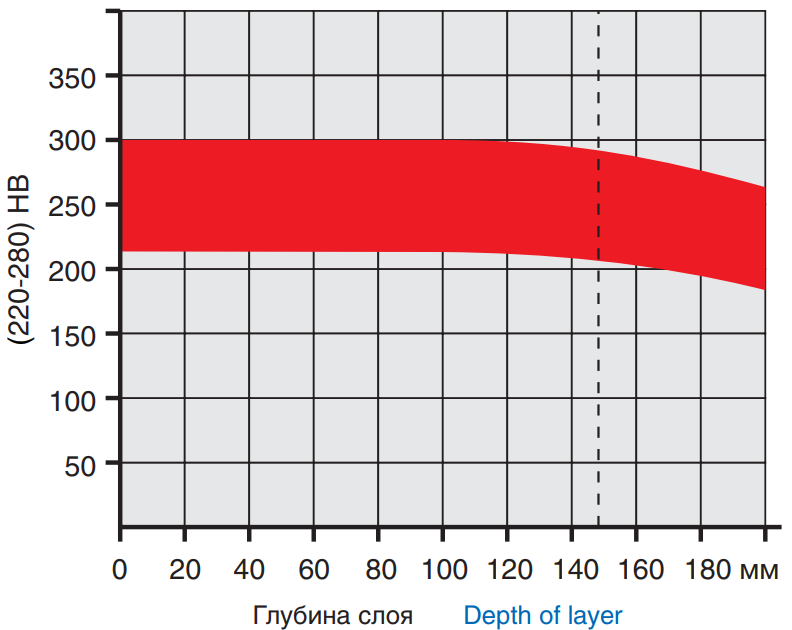

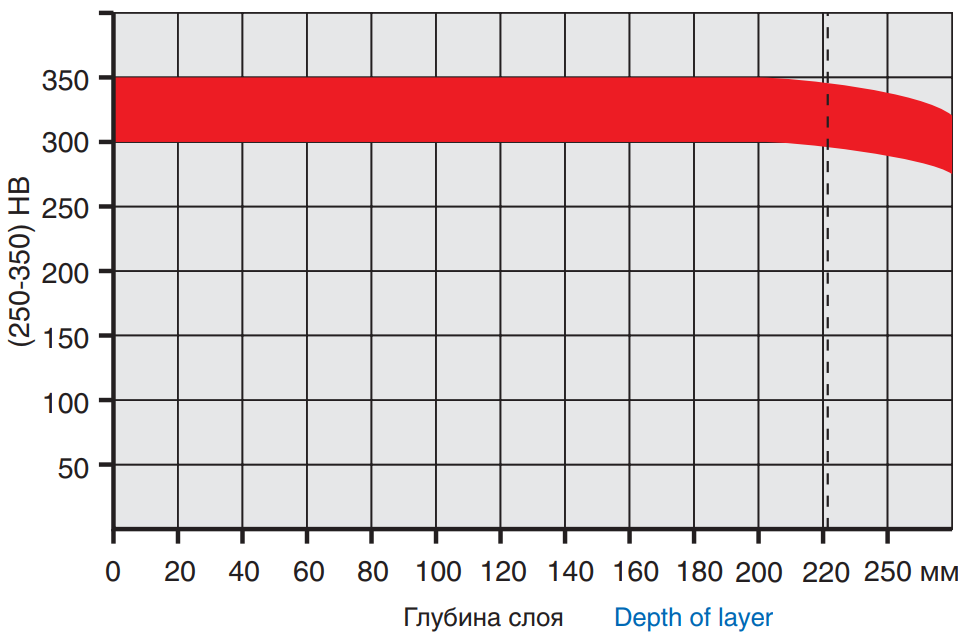

Hardness distribution along the depth of working layer

At rolls out of low-alloyed steels

Barrel hardness variation – max. 30 HB

At rolls out of high-alloyed steels